The trend of the times - New energy vehicles use mica boards for insulation and flame retardancy

Source:

Author:

Release time:

2023.02.17

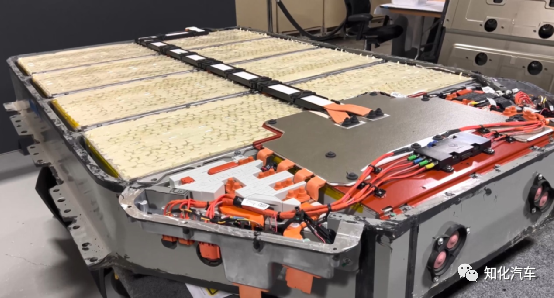

As a representative company of skateboard chassis, Rivian has achieved success in the pickup truck field. Although many people easily confuse skateboard chassis with the current CTC, the two are essentially different. CTC is an integrated innovation based on battery and chassis/body, while Rivian's skateboard chassis is more of a continuation of non-load-bearing body in the electrification field, so you will see that Rivian's battery system is a very traditional solution. Rivian uses 21700 battery cells, and the design of the battery system references the Model S/X scheme, with a semi-open module. Depending on the capacity, there are versions with 7 modules (105kWh), 9 modules (135kWh), and 12 modules (180kWh).

The above image shows the layout of the 9-module arrangement, with 4 modules arranged on each side of the box and another one placed in the front middle area. The battery pack is divided into 9 areas by 4 cross beams and one longitudinal beam in the lower box, and these structural partitions play a physical blocking role in the protection against thermal runaway spread. In addition to physical blocking, there are also mica sheets arranged between the upper cover and the modules, mainly covering each module to resist the impact and burn-through of the battery cell's thermal runaway moment on the upper cover, while also protecting against secondary hazards to electrical connections from molten ejections during thermal runaway.

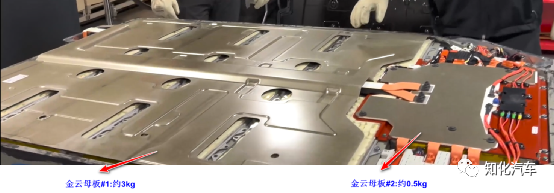

Among them, the large mica sheets weigh about 3 kilograms, while the small mica sheets weigh about 0.5 kilograms. Considering Rivian's symmetrical design of double-layer modules and Tesla's mica arrangement, there should also be corresponding protection in the area of the lower box surface facing the modules.

The design of this "shaped" large mica board seems to be a trend in recent years, including the Model S Plaid and NIO 100kWh, which have adopted this idea. The Model S Plaid has taken the application of mica to the extreme, almost covering the entire upper and lower boxes, as well as the high-voltage area, resulting in a total mica usage of an astonishing 15kg. Of course, mica is not only used for thermal protection but also for electrical insulation protection. Due to the very compact design of the S Plaid, an additional layer of insulation has been added to ensure some electrical gaps and creepage distances.

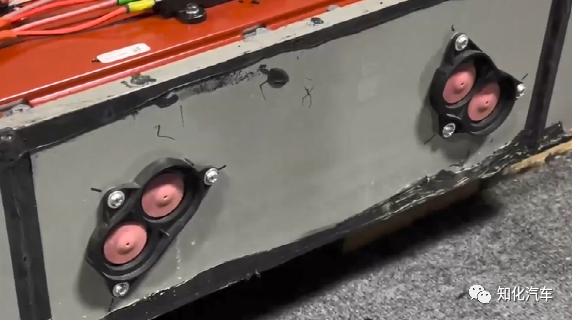

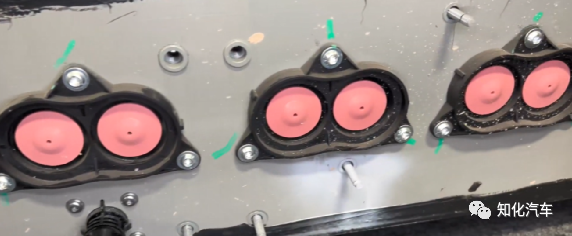

Rivian's thermal runaway venting mainly relies on vent valves at the front and rear ends of the lower box, with 2 sets and 3 sets, totaling 10. This vent valve design and its components are also derived from Tesla's design, basically the same as the Model S 1.0/1.5 generation, but the Model S 2.0 generation has mixed balance valves into the vent valves.

In addition to this main venting path, there is also a valve structure component arranged at the high and low interface on both sides (yellow circle in the image below), which is speculated to be for venting as well. Additionally, the small structural component in the red circle resembles a balance valve, but we cannot confirm it yet.

Another physical component for thermal runaway protection in the structure is the upper cover. The mass-produced Rivian has switched to steel material, and the previously claimed composite material did not become the final solution. It is speculated that there are two reasons: one is to better resist the impact of thermal runaway on the passenger compartment; the other is the rigidity and cost of fixing the upper cover.

Finally, let's look at something quite interesting: glue. In Rivian's mass production plan, its modules also incorporate a glue filling design. According to Sandy Munro's analysis, the glue used in Rivian's modules has a certain flame retardant effect, at least compared to the blue glue used in Model 3/Y, it has better flame retardant characteristics.

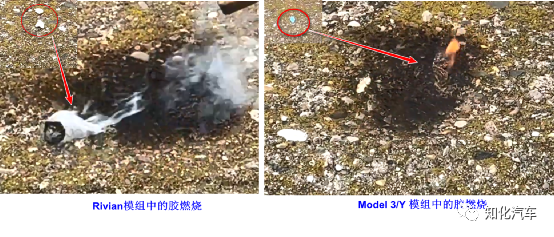

Comparing the combustion of the two types of glue,The glue used by Rivian has excellent self-extinguishing properties; basically, once the flame is removed, the glue is no longer burning, while the glue in Model 3/Y retains flames for a while after the flame is removed, but it also extinguishes quickly thereafter.

The flame retardant performance of the glue used in this area depends more on the company's own needs, while also considering cost aspects. The article is reprinted from the internet; if there is any infringement, please contact us for deletion.

Anguang Mica was founded in2012year, with its production base located in the Yuhua Mica Industrial Park in Pingjiang, Hunan, known as the "Mica Capital of China," with a factory area of9000square meters, and has a fully automated fire-resistant mica product production line.4The annual production capacity can reach3000tons, with an annual output value of nearly 100 million yuan.

Deeply engaged in the wire and cable electronic electrical insulation industry for more than10years, the company is a national high-tech enterprise. With the demand for green energy, our company utilizes years of experience in mica product production and the advantages of mica as a natural insulating material, always pursuing the development and production of high-cost performance protective insulation materials for the new energy field, energy storage power batteries, power cables, metallurgy, and other industries. We welcome everyone to call for consultation: 18627576383, and we will provide absolutely professional solutions.

Recommend Dynamics

Share